Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

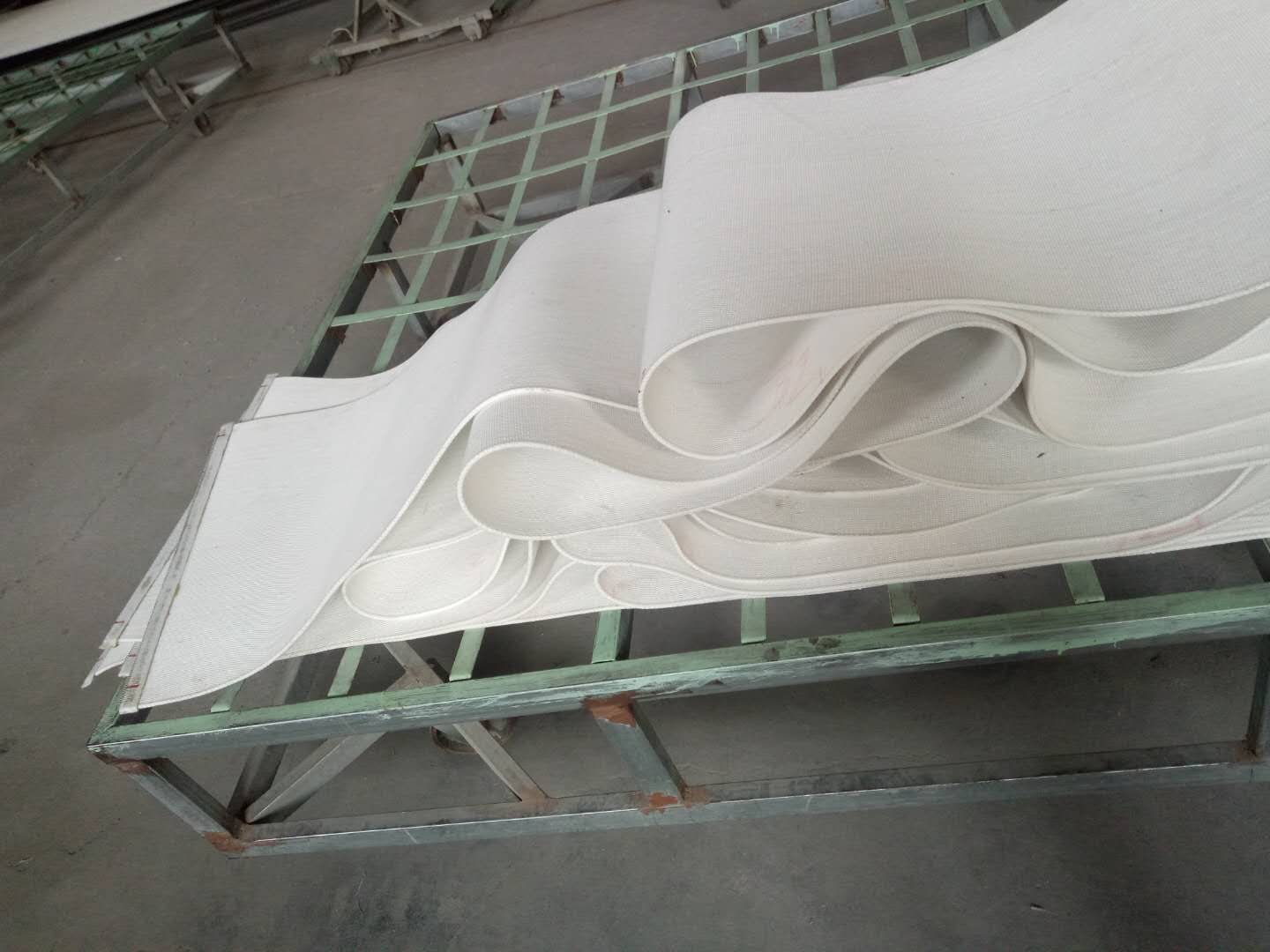

These belts have unique advantages that make them essential for the efficient operation of single facer units:

Precise Traction: Single facer traction belts provide accurate and reliable traction for the corrugated paper as it moves through the single facer machine. This ensures proper alignment, prevents paper jams, and maintains consistent corrugation quality.

Smooth Paper Transport: The smooth surface of the traction belts helps prevent paper wrinkles, creases, or damage during transportation. This is crucial for maintaining the quality of the corrugated board being produced.

Uniform Corrugation: The precise movement provided by the belts contributes to uniform and consistent corrugation of the paper. This results in corrugated board with uniform flute profiles, which is vital for achieving structural integrity and proper stacking strength.

Reduced Waste: By preventing paper jams and misalignment, single facer traction belts contribute to reduced production stoppages and material wastage. This enhances overall production efficiency and reduces costs.

High Heat Resistance: Single facer traction belts are designed to withstand the high temperatures used in the single facer machine, particularly during the bonding of the liner to the corrugated medium. Their heat resistance prevents belt deformation and extends their lifespan.

Durable Materials: These belts are typically made from durable materials that can endure the wear and tear of the single facer process. Their durability leads to longer belt life and less frequent replacements.

Customizability: Single facer traction belts come in various sizes, materials, and configurations to match different single facer machine models and production requirements. This customization ensures optimal performance.

Reduced Maintenance: Reliable traction belts require minimal maintenance, leading to less downtime for belt adjustments or replacements. This improves operational efficiency and reduces maintenance costs.

Enhanced Product Quality: By ensuring consistent paper movement and corrugation, single facer traction belts contribute to the production of high-quality corrugated boards with uniform properties. This results in stronger, more durable, and visually appealing end products.

Energy Efficiency: The efficient traction provided by these belts helps reduce energy consumption, as the single facer machinery can operate smoothly without excessive friction or paper slippage.

Operator Safety: Reliable traction belts contribute to a safer working environment by minimizing the risk of sudden machine stoppages, paper-related accidents, and misalignment issues.

High-Speed Capability: Single facer traction belts are designed to handle the high-speed operation of single facer machines, ensuring consistent and reliable paper transport even under rapid production conditions.

Corrugator Traction Conveyor Belt Specification :

|

Product |

Take Up Corrugated Belt |

|

Thickness |

6±0.3mm |

|

Width range |

400mm - 3000mm |

|

Tensile strength |

40Mpa |

|

Heat Resistance |

130℃,,accept long time pressure |

|

Weight per unit |

(3.5±0.2)kg/㎡ |

Auteur:

Mr. Maple.Zhao - Africa Market Director

E-mail:

Phone/WhatsApp:

November 30, 2024

August 21, 2023

August 21, 2023

October 08, 2024

December 14, 2023

August 21, 2023

E-mail naar dit bedrijf

Auteur:

Mr. Maple.Zhao - Africa Market Director

E-mail:

Phone/WhatsApp:

November 30, 2024

August 21, 2023

August 21, 2023

October 08, 2024

December 14, 2023

August 21, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.